BEST SELLING PRODUCTS

-

Clamping Device

Pneumatic clamping device for CO2- and powder extinguishers with pneumatic clamping cylinder.

TECHNICAL DATA model PT (No. 100 450) Dimensions (l x w x h) approx. 300 x 850 x 1000 mm Clamping surface (Ø) 80 – 220 mm Compressed-air 6 – 8 bar Color blue Optional available at extra charge:

- Equipped with adjustable clamping pressure (used for powder extinguisher)

-

Fire Hose Reels

Description:

Fire hose reels are designed and manufactured to BSEN 671-1:2001. The hose reels are manufactured from 1.5mm thick ribbed side plates for increased strength and coated with UV resistant Epoxy Powder Coating in Red, Stainless. The reel plate edge is rounded to prevent sharp edges. Hose made from natural rubber reinforced by double layer yarns. The outer and inner surfaces of the hose are smooth and seamless and can be withstand a pressure up to 20 bar.

The test pressure of the hose reel is 30 bar. The bursting pressure of the hose reel is 60 bar and above. The flexibility of the hose reel is high so that can be used without alterations for mounting with inlet to left or right of the reel.

The hose reel is fitted with specially designed glandless type drip proof seals which have been subjected to hydrostatic test pressure of 20 bar.

Steel hose reels can be supplied on request.

-

Emergency Lights – UL Listed

Description:

- Fluorescent single tube emergency light

- Working Voltage: AC220V±10%

- Battery: Nickel cadmium battery 3.6V 1.5Ah / 2.4V 4.0Ah

- Emergency duration time: 3 hours

- Working temperature: -10°C-55°C

- Working Humidity: 10% – 90%

- 1x8W T5 Fluorescent tube

- Product Size: 34. 6×10.6×7.9cm

-

Water Extinguishers

Description:

Water Fire Extinguishers are effective on class A fire.

All Extinguishers are coated internally for optimal protection against rust and corrosion.

The valve is provided with safety release valve to release the excess pressure.

Cylinders of different capacity can be supplied upon request.

Water Fire Extinguishers are cost-effective

-

Dry Powder Fire Extinguisher Filling Machine

Dry Powder Fire Extinguisher Filling Machine is a new model improved by our factory. It can suck dry powder into the cylinder quickly by vacuum. It has several advanced features, such as small volume, easy movement, simple operation, and environmental protection. It is especially suitable for the filling, production, and maintenance of dry powder extinguisher and also suitable for filling various powder products. It is ideal equipment in the powder filling industry

-

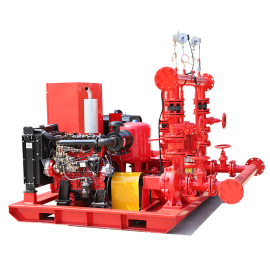

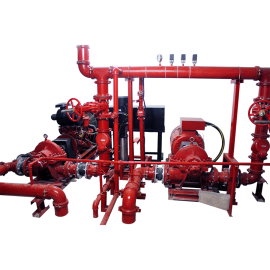

Fire Pumps

Description:

Fire pumps are used to boost the water pressure in sprinkler and standpipe systems and to deliver the required amount of water.

- Easily access to all working parts

- Rugged construction

- Efficient Operation

- Self-Venting Design

- Dynamic balanced Impeller

- Performance and Hydrostatic test

- Space saving design

- Available in 50 or 60 Hz

Available Pumps Type:

End Suction Pump

Horizontal Split Case

-

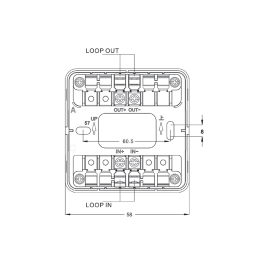

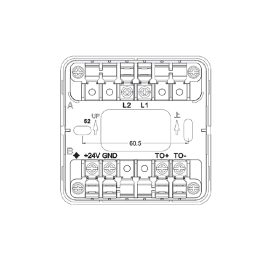

Addressable Smoke Detector

Description:

There are certain situations that a smoke detector would not be enough in fire management and safety. In instances of smoldering fires, addressable smoke detectors would be the best choice. This smoke detector would be ideal for dense smokes of fires that were produced from the burning of soft furnishing, plastic, foam, or similar materials that easily smolders.

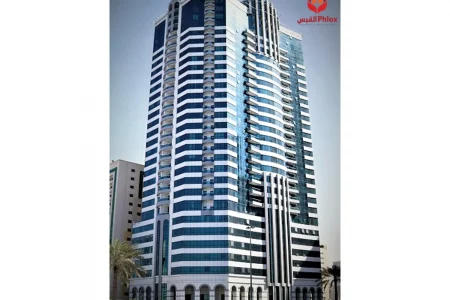

PHLOX Security & Safety Equip. LLC is a fire fighting and fire alarms supplier based in Sharjah, UAE. In terms of fire safety and prevention, we are a leading expert and we also install fire-prevention alarms and systems. We have a wide range of products for different fire-preventive measures needed, and we, specifically, offer the GST DC-9103E Conventional Rate of Rise and Fixed Temperature Heat Detector.

The GST DC-9103E is a new generation product of GST that works stably by being fixed with a highly reliable fire judging program. It is also built with a microprocessor enabling a compact design. When detecting fire signals, it can change its own current to transmit the proper signal to the fire alarm control panel or the location of the addressable zone monitor unit. This smoke detector will keep illuminating fire LED until it is reset by its own system ensuring that the signal would be well received by people within the vicinity of the hazard.

Other unique features of the model are its programmable classes enabling up to 3 classes of program. It also has a reed switch testing. Its design is sleek and aesthetically pleasing allowing a low-profile and unobtrusive design that can easily complement any modern building. It is also electronically addressed and it comes with a remote indicator as its output terminal. The LED contained in the smoke detector also allows 360O viewing and smoke detection. Lastly, the product complies with EN 54-5.

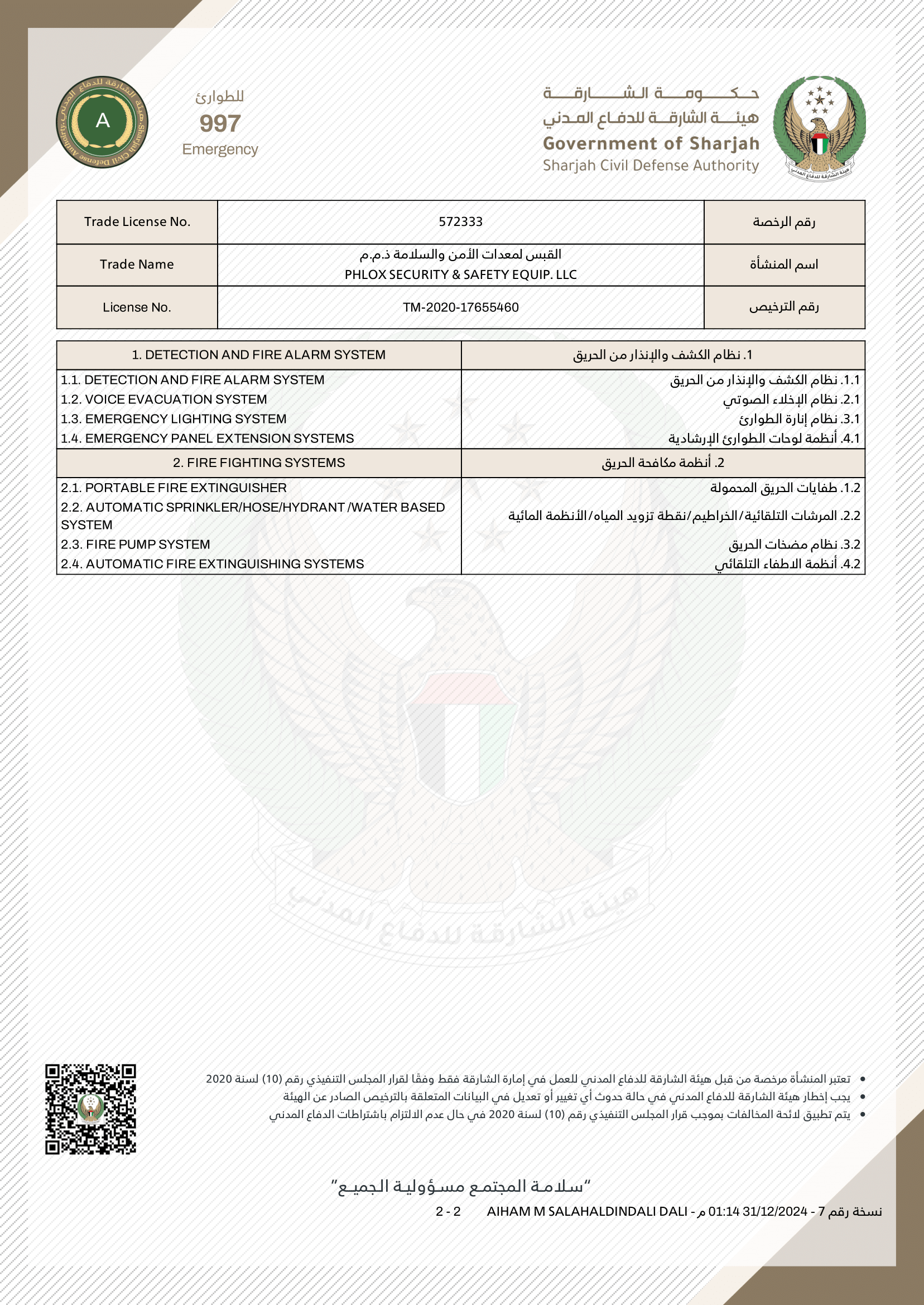

CERTIFICATIONS

Fire Safety is one of the crucial aspects of any construction project as well as the existing safety plan and maintenance. Our completed projects and wide range of portfolio is a testament to our capability and confidence to undertake any project in the emirate.